So I had sawn off the bottom of the Hornet and thought that all I would need to do was rebuild the book material and put some rods in the legs and reassemble the two halves.

Thinking about how I would go about this I decided to further cut off the books from the base and have a clearer pathway for my book rebuilding.

The rot was more than I imagined and realized no rods in the legs were going to do it. A support frame structure was going to be necessary and it would have to carry the 300-400 pound weight of the upper half of the Hornet.

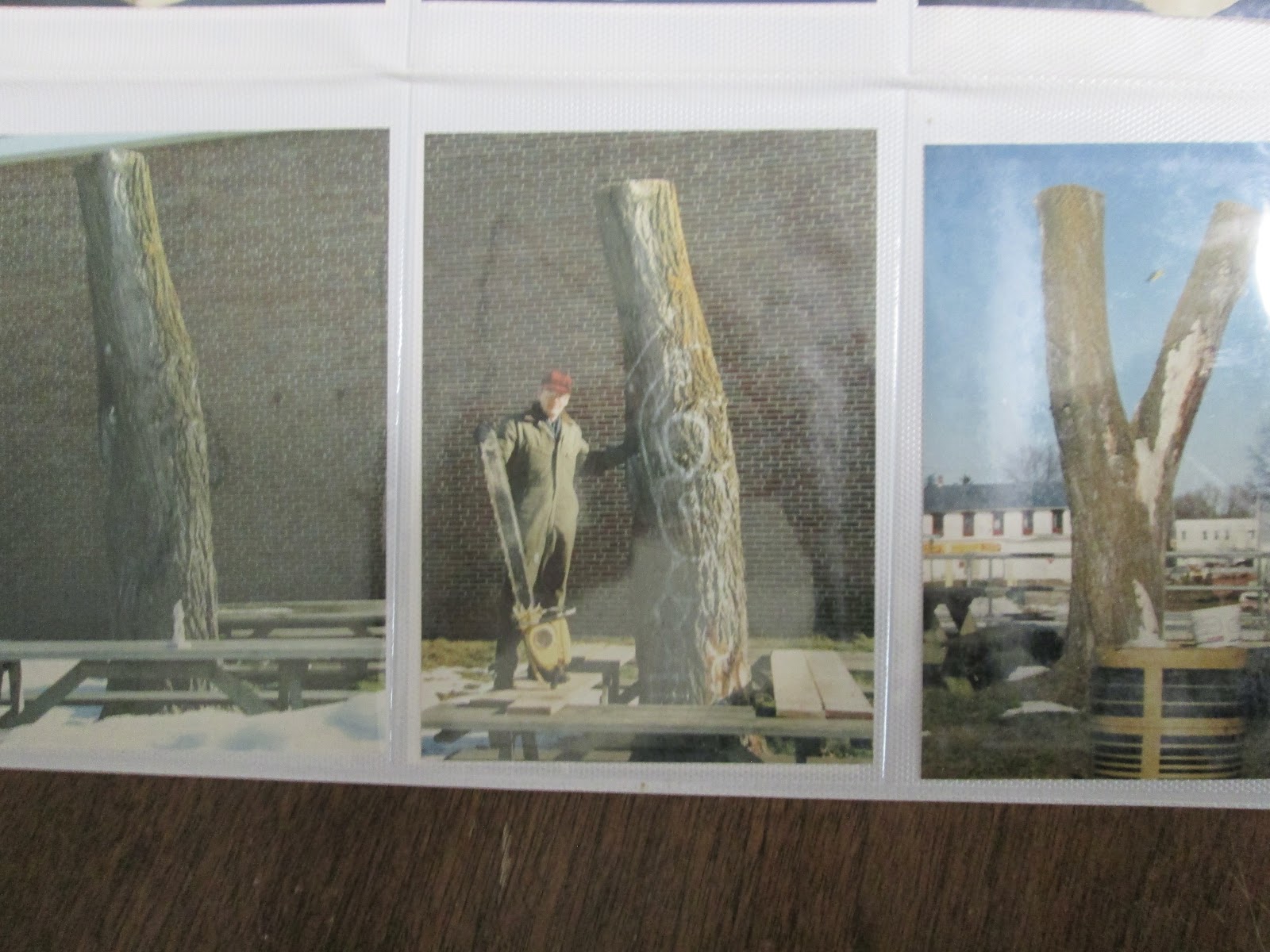

I brought the upper half of the Hornet home in my truck and put it on a low trailer. As I moved it from the truck I began to realize that the ol' Hornet was rotten to the core!

Major surgery was required so I could get a better look at the Hornet's insides. As the line in the song goes, "the first cut is the deepest".

The insides were a soft pulp. However this proved to be a good thing as now the center of the Hornet would be open and I could design and build my support structure.

Working from the bottom up I had rebuilt the book with some treated 1x6's. In the base I welded two sets of 1/2" rebar about 6" apart to the four angle iron legs that mount the Hornet to the four 6x6's base.

It was now a matter of going from the rebar cage with some vertical rods to set the books on. These rods would carry only the 10 pounds of book weight.

OK so now I had to figure out a way to get some major 3/4" rebar to come up through the 1" hole I drilled in the right leg stump. I would then weld and brace this rebar to the bottom 1/2" rebar cage.

I had an opening for a piece of 5/8" rebar to come up through the books and other leg. Now I had two points to work with.

Time to bring over the front half go the body. This was hoisted up into place with a chain fall that I hung on a tree limb in the yard.

Using some plates and GRK screws I secured the front half of the body in place. I need to have three rods to form a triangle to support the 300 to 400 pounds of Hornet weight.

I would need to have the back half of the body in place so I could determine where the three rods would go so as not to interfere with the two half when being reassembled.

It took a bit of sawing to clear the way for the rods that were welded onto the base rods. Now the entire weight of the Hornet went through the rods and was carried by the 4 angle iron base mounts going to the four 6x6's in the ground. Since the remaining wood was to thin to handle any weight or pressure from straps to lift it back into place I welded a 1/2" long nut at the top of the three rods. Into this a 2" eye screw would be threaded and the Hornet could be easily lifted from one point on the head.

So can I get it all back together ?