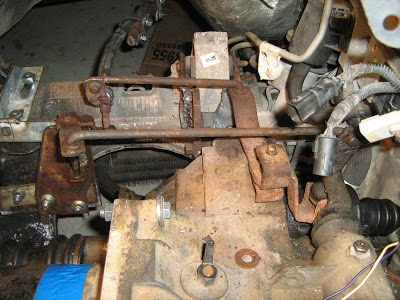

A bit of an extension needed to be fashioned and attached to the lengthen the linkage to the shift knob and can be seen at the top of the photo.

Then I got distracted by the pine logs I had collected this summer and started thinking about another log cabin only this time I would try my hand at hewing the logs by hand too. Call me crazy (I even thought that this might not be to smart but then I tried it) but I think this is dooable! After all they did it 100 years ago without a second thought, right?

I used a nice straight 2x4 as a guide to draw lines the length of the log ( I tried a chalk line but had no success with it, laser too).

My tool of choice will be an 8 inch broad axe. I "researched" the process of hewing a log on the internet and watched several U tube clips on the process. Each attacked the log by chopping down, parallel to the surface that was to be flattened. This required straddling the log or standing along side and swinging the axe in such a way that put one's legs and knee caps in harms way! As you can see in the two pictures above the broad axe is sharpened with a bevel on only one side. Why (this would be important)?

After 2 hours doing one side of one log the way I "saw it on the internet" I thought no way! Even though I got better at it doing the second side I still felt that the process of hewing logs for cabins must have been one of the reasons early pioneers had strong arms but died young. I discussed this process with a cabin building friend and he asked if I was chopping perpendicular to the log like he did? See picture above. I had seen him do this on some of the replacement logs we had made for his cabin a year ago and rejected the technique out of hand because "I saw it on the internet" and no one did it that way. After talking with him I went home and thought I had nothing to loose and gave it a try. I thought about it and to me it seemed logical to chop with the bevel up so I did. The results were very poor and I again rejected this approach because "I saw it on the internet" and convinced myself of it. When I shared my attempt and poor performance using his method, Tom said, he would stop by and give it a try. When he arrived he took the axe and began to chop away. The chips exploded off the log and he made more progress in 5 minutes than I did in half an hour! I was dumb founded he was chopping with the BEVEL DOWN. Each chop split a good 1 inch deep piece of wood off the log. On the return pass the chips that remained were cleaned off and the surface smoothed down.

One 16 foot log in an about an hour, not bad. I think this is dooable! Bevel side down and I have not seen that on the internet. Now back to work on the EV battery box.

No comments:

Post a Comment